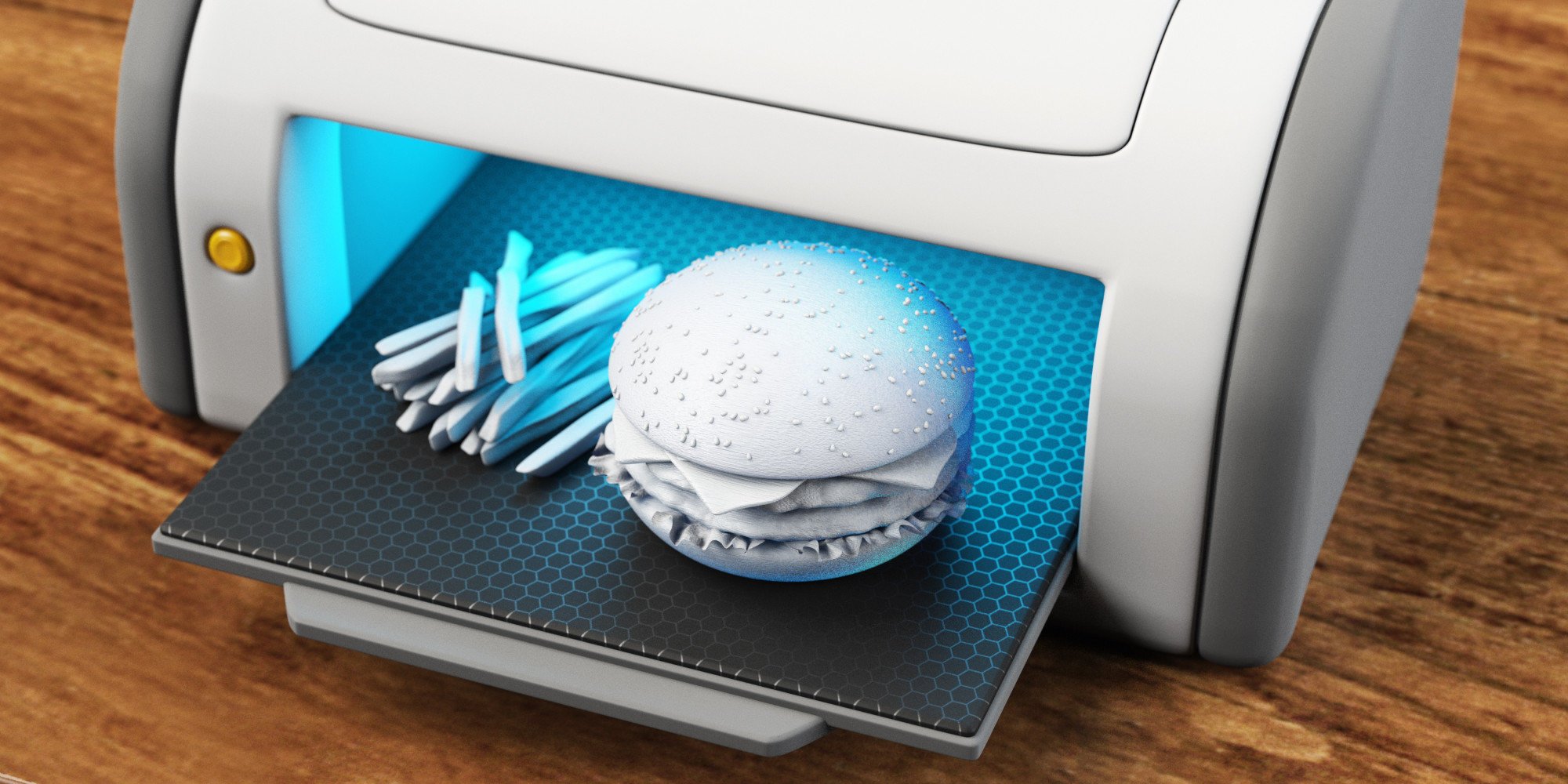

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Prepare a 3D model before it is ready to be 3D printed. This is what they call slicing. The technology was first invented in the 1980s, and since that time has been used for rapid prototyping (RP). However, in the last few years, 3D printing has additionally started to evolve into a next-generation manufacturing technology that has the potential to allow the local, on-demand production of final products. It is possible to 3D print in hundreds of different plastic, metal and ceramic materials, with pioneers now 3D printing molds, aerospace components, jewelry, works of art, toys and medical devices.The process of creating cell patterns in a confined space using 3D printing technologies, where cell function and viability are preserved within the printed construct is called bioprinting.

Bioprinting can be defined as the use of computer-aided transfer processes for patterning and assembling living and non-living materials with a prescribed 2D or 3D organization in order to produce bio-engineered structures serving in regenerative medicine, pharmacokinetic and basic cell biology studies.

From my personal experience I can say that, this is the future of human organ replacement since my father is aged 80 years and since his denture has become loose. Dentists say that even the standard procedures will not be helpful in creating a denture which fits him perfectly. Here 3D printing when in its advanced stage implemented in India can help him.

Mohan P. | Assistant General Manager

Jain Software Foundation .