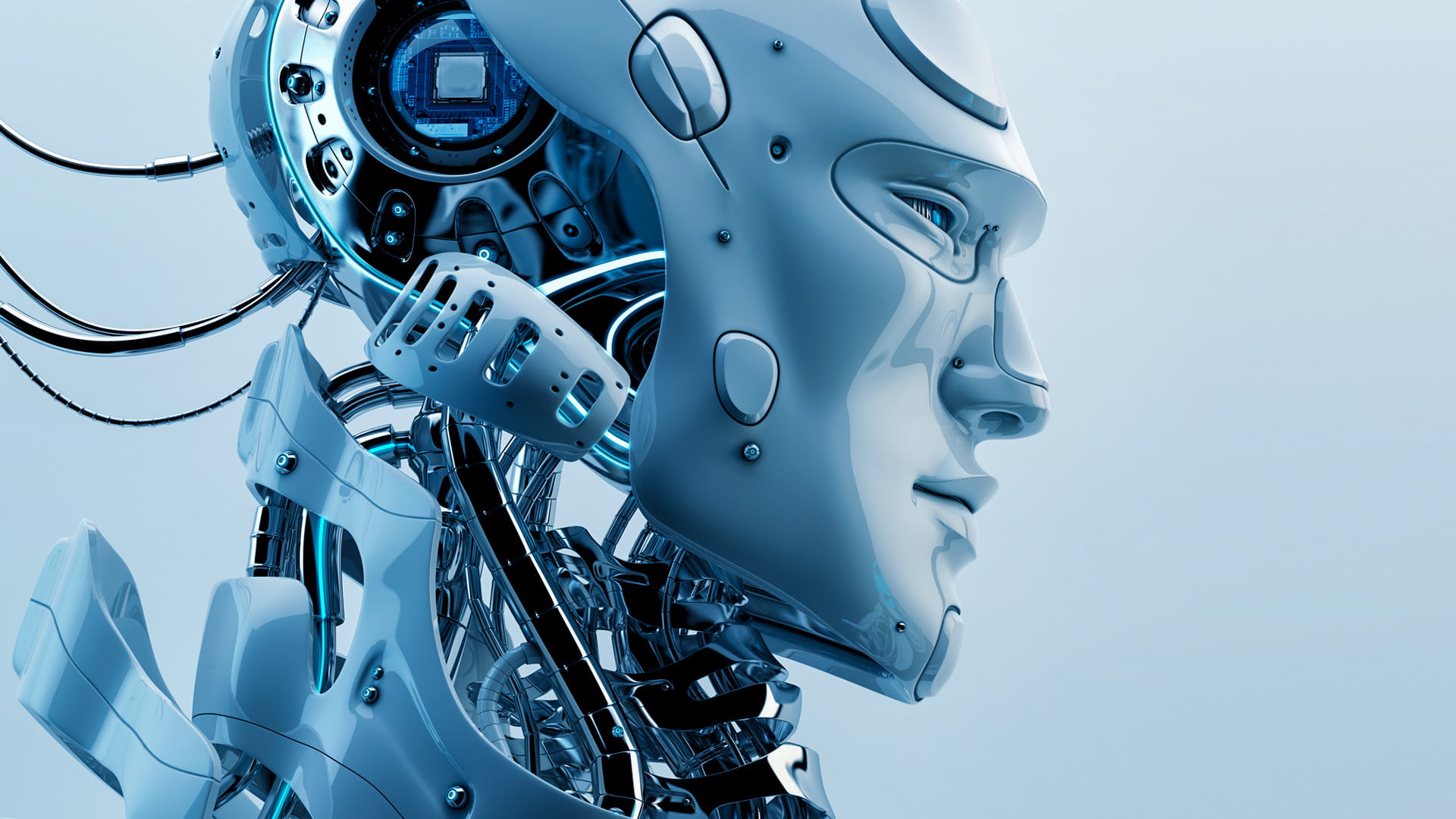

Robotics – The Future of Intelligent Automation

By Author – Faizan Haider

Robotics is a fascinating branch of engineering and science that brings together mechanical engineering, electrical engineering, and computer science. It focuses on designing, constructing, operating, and using robots, along with developing computer systems that enable control, sensory feedback, and data processing.

In simpler terms, robotics is all about creating machines that can perform tasks traditionally done by humans. This field overlaps with electronics, artificial intelligence, mechatronics, nanotechnology, and bioengineering. Today, robotics plays an essential role in industries, medical science, defense, and even in household automation.

What is Robotics?

Robotics involves designing and developing machines that can substitute for humans and replicate human actions. These robots are used in a variety of settings — from dangerous environments like bomb detection and deactivation to manufacturing processes and space exploration. Some robots are even designed to resemble humans, making their interaction more natural in tasks that involve communication or physical assistance.

Modern robots are often inspired by nature, giving rise to “bio-inspired robotics,” which imitates natural forms and movements to achieve better efficiency and flexibility.

Uses of Robotics

Robots are ideal for performing repetitive or dangerous tasks that would be difficult or unsafe for humans. For example, robots are used to enter and inspect buildings with potential explosives, handle hazardous materials, or operate in extreme environments. In manufacturing, robots build automobiles, assemble electronics, and even package food products with unmatched speed and precision.

How Robotics Works

Every robot requires a power source to operate — usually a battery or direct power connection. Some use hydraulic pumps or pneumatic compressors depending on their design. These robots are powered by electrical circuits that control motors and valves to enable movement.

The core of every robot is its computer controller, which manages its functions. The controller activates motors, interprets sensor data, and executes programmed instructions to make the robot act accordingly. Most robots can be reprogrammed simply by updating their software.

Not all robots have sensory systems, but many modern robots include sensors to monitor their surroundings or their own motion. For example, robots use light sensors, infrared beams, or cameras to measure movement and positioning. This allows precise control of their actions — similar to how a computer mouse tracks movement using optical sensors.

Purpose of Robotics

Robots are primarily designed to handle tasks that are dull, dirty, or dangerous. Activities like welding, grinding, molding, or casting can be efficiently performed by robots, freeing human workers for more creative or decision-oriented roles. Robots do not tire or lose concentration, making them ideal for repetitive industrial processes that require consistency and precision.

Functions of Robotics

A typical robot consists of a movable structure, motors, sensors, a power source, and a computer “brain.” In essence, robots are mechanical beings that mimic human or animal capabilities — from movement and manipulation to perception and decision-making.

Parts of a Robot

-

Controller (Brain): Acts as the command center, processing information and controlling all other parts of the robot.

-

Actuators (Muscles): Responsible for movement by converting energy into motion.

-

Sensors (Eyes and Ears): Detect environmental conditions like temperature, pressure, or proximity.

-

Power Supply (Heart): Provides the energy necessary for the robot’s operations.

-

Body (Structure): The physical framework that holds everything together.

Uses of Sensors in Robotics

Sensors play a crucial role in allowing robots to interact intelligently with their environment. They measure physical factors such as temperature, light, sound, pressure, and humidity, sending data to the robot’s processor. For instance, a security system may use infrared sensors that trigger an alarm when a beam is broken. Similarly, industrial robots use sensors to maintain precision and safety during manufacturing.

Advantages of Using Robots

-

Increased Precision: Robots perform tasks with high accuracy and consistency, reducing errors.

-

Improved Safety: They can handle dangerous jobs, minimizing risk to human workers.

-

Enhanced Productivity: Robots can work 24/7 without fatigue.

-

Medical Innovation: In healthcare, robots assist in complex surgeries like prostate and heart operations, ensuring better precision and outcomes.

-

Flexibility: Modern robots can be reprogrammed to handle different tasks across industries.

Conclusion

Robotics represents one of the most transformative technologies of our era. From automating industrial tasks to performing life-saving surgeries, robots are redefining how humans interact with machines. As technology advances, robotics will continue to evolve, blending artificial intelligence and automation to make life easier, safer, and more efficient.

References: Jain Software